- Home

- Distribution

- AMR MILVUS

Enhance your material transport capabilities – even in the busiest warehouse or production environments – with SEIT robots. Made by Milvus Robotics, these reliable and safe AMRs efficiently move materials with no human intervention required. They work seamlessly alongside people, forklifts, and other equipment. Requiring no infrastructure, SEIT robots are suitable for a range of manufacturing environments, distribution centers and more.

PAYLOAD: 100 KG

LOAD TYPE: APPLICATION SPECIFIC - ON TOP LOADING, CONVEYOR, LIFT

MAX SPEED: 1.5 M/S

DIMENSIONS (LXWXH): 820 MM X 630 MM X 297 MM

NAVIGATION SYSTEM: NATURAL NAVIGATION

COMMUNICATION: WIFI

POSITIONING ACCURACY: ±1 CM, ±1 DEG

INTERFACE: WEB BASED SOFTWARE INTERFACE

SAFETY FEATURES: SAFETY LIDAR, EMERGENCY STOP BUTTONS, INDICATOR LIGHT BARS

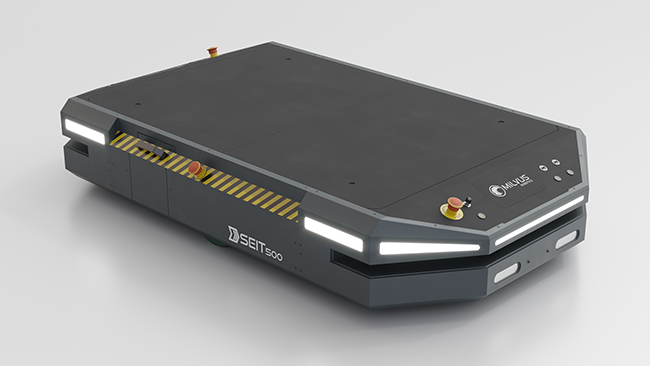

PAYLOAD: 500 KG

LOAD TYPE: APPLICATION SPECIFIC - ON TOP LOADING, CONVEYOR, LIFT

MAX SPEED: 1.5 M/S

DIMENSIONS (LXWXH): 1650 MM X 950 MM X 297 MM

NAVIGATION SYSTEM: NATURAL NAVIGATION

COMMUNICATION: WIFI

POSITIONING ACCURACY: ±1 CM, ±1 DEG

INTERFACE: WEB BASED SOFTWARE INTERFACE

SAFETY FEATURES: 2 SAFETY LIDARS, EMERGENCY STOP BUTTONS, INDICATOR LIGHT BARS

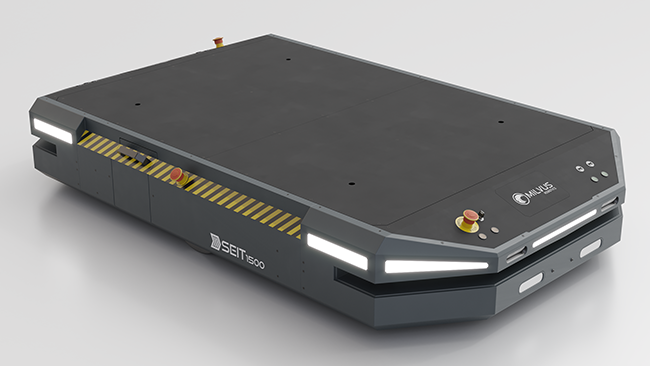

PAYLOAD: 1500 KG

LOAD TYPE: APPLICATION SPECIFIC - ON TOP LOADING, CONVEYOR, LIFT

MAX SPEED: 1.5 M/S

DIMENSIONS (LXWXH): 1800 MM X 1080 MM X 297 MM

NAVIGATION SYSTEM: NATURAL NAVIGATION

COMMUNICATION: WIFI

POSITIONING ACCURACY: ±1 CM, ±1 DEG

INTERFACE: WEB BASED SOFTWARE INTERFACE

SAFETY FEATURES: SAFETY LIDAR, EMERGENCY STOP BUTTONS, INDICATOR LIGHT BARS

INFRASTRUCTURE FREE

SEIT allows you to navigate throughout the facility or your warehouse, without having to commit any of your resources on infrastructure. SEIT’s navigation requires no physical markers, such as, magnets, beacons, wires or tapes. This means, there will be no interruption to your operation and no physical changes to your facility. Furthermore, the lack of fixed infrastructure not only provides an initial savings, but also signifies a reduction in future infrastructure costs as these tooling and equipment undergo wear and tear, or might be replaced all together if the production lines change.

PRECISE

Precise, is one of the many words that we can use to describe SEIT. But perhaps, it is one of the most crucial ones since manufacturing requires exact precision. SEIT can provide this level of precision, following your commands and execute them on time, repeatedly and consistently, saving you to worry from possible downtime and the costs come with it.

SAFE

SEIT is compatible with recent international safety standards. Furthermore, SEIT’s proactive sensing capabilities not only prevents accidents, but they also benefit the users in terms of reduced accidents and injuries as well as less compensation in these regards.

CREATES VALUE

SEIT allows you to reduce transportation related wastes, or in other words, non-value adding operations. Through reorganizing the movement on the production and manufacturing site, it guarantees an efficient and consistent delivery of materials – which in turn, presents you the option to redistribute your workforce within value-creating roles if desired.

DURABLE AND STRONG

SEIT is designed to withstand heavy loads, undertake most arduous tasks and work under harsh environmental conditions. Capable of carrying loads up to 500 kg, SEIT is built with industry standard components that are highly durable and reduce maintenance costs drastically.

is a registered trademark of TNS SERVIS s.r.o.

+420 573 034 358

TNS SERVIS s.r.o.

Division ZLÍN ROBOTICS®

K Teplinám 619, 76315 Slušovice, Czech Republic

CRN: 291 81241, VAT Reg. No.: CZ291 81241

Company registered in the Commercial Register maintained by the Regional Court in Brno, file number C63717